Rice team progresses in quest for reliable, flexible computer memory

Very few discoveries happen in an instant. Few discoverers go, “Aha!”

More often, the truth reveals itself to scientists the same way a statue comes to light as a sculptor chips away.

This happens even when the work of art is on the nanoscale, where individual things make a strand of hair look like a redwood by comparison.

Authors of the 2010 paper that described a new type of silicon oxide memory, clockwise from left, Rice Professors Doug Natelson and Lin Zhong, then-graduate students Zhengzong Sun and Jun Yao, and Professor James Tour. Photo by Jeff Fitlow

More than four years ago, a collection of students, postdoctoral researchers and professors at Rice University found themselves chiseling down into a mystery involving two of the most basic, common elements on Earth: carbon and silicon oxide.

The group led by chemist James Tour came to a discovery of note: that it was possible to make bits of computer memory from those elements, but make them much smaller and perhaps better than anything on the market even today.

From that first revelation in 2008 to now, Tour and his team have steadily advanced the science of two-terminal memory devices, which he fully expects will become ubiquitous in the not-too-distant future.

The latest dispatch is a paper in the journal Nature Communications that describes transparent, non-volatile, heat- and radiation-resistant memory chips created in Tour’s lab from those same basic elements, silicon and carbon. But a lot has happened since 2008, and these devices bear only a passing resemblance to the original memory unit.

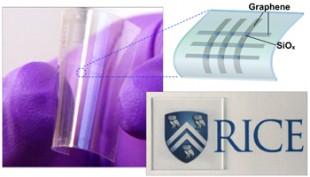

In the new work, Tour and his co-authors detail their success at making memory chips from silicon oxide sandwiched between electrodes of graphene, the single-atom-thick form of carbon.

Even better, they were able to put those test chips onto flexible pieces of plastic, leading to paper-thin, see-through memories they hope can be manufactured with extraordinarily large capacities at a reasonable price. Think about what that can do for heads-up windshields or displays with embedded electronics, or even flexible, transparent cellphones.

“The interest is starting to climb,” said Tour, Rice’s Rice’s T.T. and W.F. Chao Chair in Chemistry as well as a professor of mechanical engineering and materials science and of computer science. “We’re working with several companies that are interested either in getting their chips to do this kind of switching or in the possibility of making radiation-hard devices out of this.”

In fact, samples of the chips have climbed all the way to the International Space Station (ISS), where memories created and programmed at Rice are being evaluated for their ability to withstand radiation in a harsh environment.

Using graphene as crossbar terminals, Rice researchers are following through on groundbreaking research that shows silicon oxide, one of the most common materials on Earth, can be used as a reliable computer memory. The memories are flexible, transparent and can be built in 3-D configurations. Graphic by Jun Yao/Rice University

“Now, we’ve seen a couple of DARPA announcements asking for proposals for devices based on silicon oxide, the very thing we’ve shown. So there are other people seeing the feasibility of this approach,” Tour said.

It wasn’t always so, even if silicon oxide “is the most studied material in humankind,” he said.

“Labs in the ’60s and ’70s that saw the switching effect didn’t have the tools to understand what they were looking at,” he said. “They didn’t know how to exploit it; they called it a soft breakdown in silicon. To them, it was something bad.”

In the original work at Rice, researchers put strips of graphite, the bulk form of carbon best known as pencil lead, across a silicon oxide substrate and noticed that applying strong voltage would break the carbon; lower voltages would repeatedly heal and re-break the circuit. They recognized a break could be a “0” and a healed circuit a “1.” That’s a switch, the most basic memory state.

Manufacturers who have been able to fit millions of such switches on small devices in the likes of flash memory now find themselves bumping against the physical limits of their current architectures, which require three wires – or terminals – to control and read each bit.

But the Rice unit, requiring only two terminals, made it far less complicated. It meant arrays of two-terminal memory could be stacked in three-dimensional configurations that would vastly increase the amount of information a chip could hold.

And best of all, the mechanism that made it possible turned out not to be in the graphite, but the silicon oxide. In the breakthrough 2010 paper that followed the 2008 discovery, the researchers led by then-graduate student Jun Yao found that a strong jolt of voltage through a piece of silicon oxide stripped oxygen atoms from a channel only 5 nanometers wide, turning it into pure silicon. Lower voltages would break the channel or reconnect it, repeatedly, thousands of times.

“Jun was the first to recognize what he was seeing,” Tour said. “Nobody believed him, though (Rice physicist) Doug Natelson said, ‘You know, it’s not out of the realm of possibility.’ The people on the graphitic memory project were not at all excited about him saying this and they argued with Jun tooth and nail for a couple of years.”

Yao struggled to convince his lab partners the switching effect wasn’t due to the breaking graphite but to the underlying crystalline silicon. “Jun quietly continued his work and stacked up evidence, eventually building a working device with no graphite,” Tour said. Still, he recalled, Yao’s colleagues suspected that carbon in the system skewed the results. So he demonstrated another device with no possible exposure to carbon at all.

Astronaut Akihiko Hoshide, a member of Expedition 32 to the International Space Station (ISS), poses earlier this year with a floating display of components of the HiMassSEE experiment. The package at lower left contains silicon oxide-based memory chips designed at Rice. Photo courtesy NASA

Yao’s revelation became the basis for the next-generation memories now being designed in Tour’s lab, where silicon oxides sandwiched between graphene layers are being attached to plastic sheets. There’s not a speck of metal in the entire unit (with the exception of leads attached to the graphene electrodes). And the eye can see right through it.

“Now we’re making these memories with about an 80 percent yield of working devices, which is pretty good for a non-industrial lab,” Tour said. “When you get these ideas into industries’ hands, they really sharpen it up.”

The idea of transparency came later. “Silicon oxide is basically the same material as glass, so it should be transparent,” Tour said. Graphene sheets, single-atom-thick carbon honeycombs, are almost completely transparent, too, and tests detailed in the new paper showed their ability to function as crossbar electrodes, a checkerboard array half above and half below the silicon oxide that creates a circuit where the lines intersect.

The marriage of silicon and graphene would extend the long-recognized utility of the first and prove once and for all the value of the second, long touted as a wonder material looking for a reason to be.

“It was a very rewarding experience,” said Yao, now a postdoctoral researcher at Harvard, of his work at Rice. “I feel grateful that I stumbled on this, had the support of my advisers and persisted.”

By good fortune, Yao was the rare graduate student with three advisers. As confusing as that may have seemed at the start of his Rice career, it was luck those advisers were digital systems expert Lin Zhong and condensed matter physicist Natelson, both rising stars in their fields, and Tour, a renowned chemist.

Each made important contributions to the project as it progressed. “Doug had very acute intuition about the underlying mechanism, and we constantly turned to Lin for his advice on the electronic architecture,” Yao said.

Getting his story on Page 1 of the New York Times was enough of a thrill, but another was ahead as NASA decided to include samples of his chip in an experimental package bound for the space station. The day of Yao’s planned departure for his postdoctoral job in Cambridge, Aug. 24, 2011, was to be the best of all as the HIMassSEE project lifted off from Central Asia aboard a cargo flight to the ISS. Minutes later, the unmanned craft crashed in Siberia.

Nearly a year later, a new set of chips made it to the ISS, where they will stay for two years to test their ability to hold a pattern when exposed to radiation in space.

In the meantime, Yao passed responsibility for the project to Jian Lin, a co-author of the new paper who joined the Tour and Natelson labs in 2011 as a postdoctoral researcher. Lin built the latest iterations of silicon oxide memories using crossbar graphene electrodes.

“Our lab members are excellent at synthesizing materials and I’m good at fabrication of devices for various applications, so we work together well,” said Lin, whose primary interest is in the application of nanomaterials. “This group is a win-win for me.”

Labs at other institutions have picked up the thread, carrying out their own experiments on silicon oxide memory. “The switching mechanism has pretty much been investigated,” Lin said. “But from engineering or application perspectives, there are a lot of things that can be done.”

So here silicon memory stands, a toddler full of promise. Researchers at Rice and elsewhere are working to increase silicon memory’s capacity and improve its reliability while electronics manufacturers think hard about how to make it in bulk and put it into products.

Tour realizes impatience for scientific progress is a function of hurried times and not a failure of the process, but he counsels against frustration. “It’s a very interesting system that has been slow to develop,” he said, “as we’ve been working to understand the fundamental switching mechanism,” a task largely accomplished by Yao and his Rice advisers in a paper published earlier this year. “This is now transitioning slowly into an applied system that could well be taken up as a future memory system.

“It is a good example of basic research,” he said. “Now, others have to be able to look forward from the science and say, ‘You know, there’s a path to a product here.'”

Co-authors of the Nature Communications paper are Rice graduate students Yanhua Dai, Gedeng Ruan, Zheng Yan and Lei Li. Zhong is an associate professor of electrical and computer engineering. Natelson is a professor of physics and astronomy and of electrical and computer engineering.

The research was supported by the David and Lucille Packard Foundation, the Texas Instruments Leadership University Fund, the National Science Foundation and the Army Research Office.

Leave a Reply